CNC Turning

Whether of a short run or in large volume, Profile’s precision CNC Turning practices achieve a lower cost per part in a shorter lead time for nearly any small to medium sized component.

Our newest CNC turning center- with Y-axis and subspindle-equipped, provides economical production of more complex parts in fewer operations.

We also succeed with hard turning operations for hardened parts having low length-to-diameter ratios. Hard turning generally eliminates subsequent grinding operations, and works well for various steels, Inconel, and other exotics.

Can you believe that turning a work piece to form it dates back to 1300 BC? Ancient Egyptians developed the two-person lathe, where one person used a rope to spin the work piece while another held a forming tool to it, shaping it symmetrically.

Over the centuries, multiple cultures have contributed to the turning lathe’s development. But it wasn’t until the 1970s that computerized numerical control (CNC) provided the lathe its digital mastery. And since, their advances in tool and work holding achieve both symmetrical and non-symmetrical geometries to the tenth of an inch!

Contact us today to discuss your CNC turning projects!

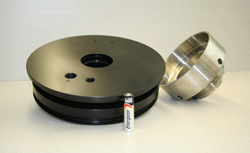

| Length: to 25″, approx. Outer Diameter: 10″, approx. 2.5″ thru-spindle bar feed Tolerance: +/- 0.0002″ Finish: 16µ (microinch) |

Boring & Reaming Drilling & Tapping Broaching & Knurling Grooves & Slots ID/OD Threading Contour & Form Turning |

| Steels (all types) Aluminum Brass & Bronze Titanium & Tungsten Hastalloy & Inconel Plastics Powdered Metals |

Adaptors & Fittings Ball Seats & Discs Bushings & Guides Connectors & Couplings Glands & Housings Sensors & Arrestors Shafts & Sleeves |

1 Mori-Seiki DuraTurn 2050 with 8” chuck, 2 ½” bar feed capacity

1 Mori-Seiki NL-2000 with 8” chuck, 2 ½” bar feed capacity, and live tooling

1 Hitachi-Seiki HiTec-Turn 23 SII with 10” chuck, 2 ½” spindle ID

1 Doosan Lynx 220LSY with 8″ chuck, 5″ subspindle, Y axis, and live tooling