Quality Commitment

Quality is more than the finished product. It’s the process, the people, the discipline- everything. It is our essential commitment.

When you need a reliable manufacturing partner, know that Profile’s best-of-breed quality practices will exceed your expectations.

To deliver on that promise:

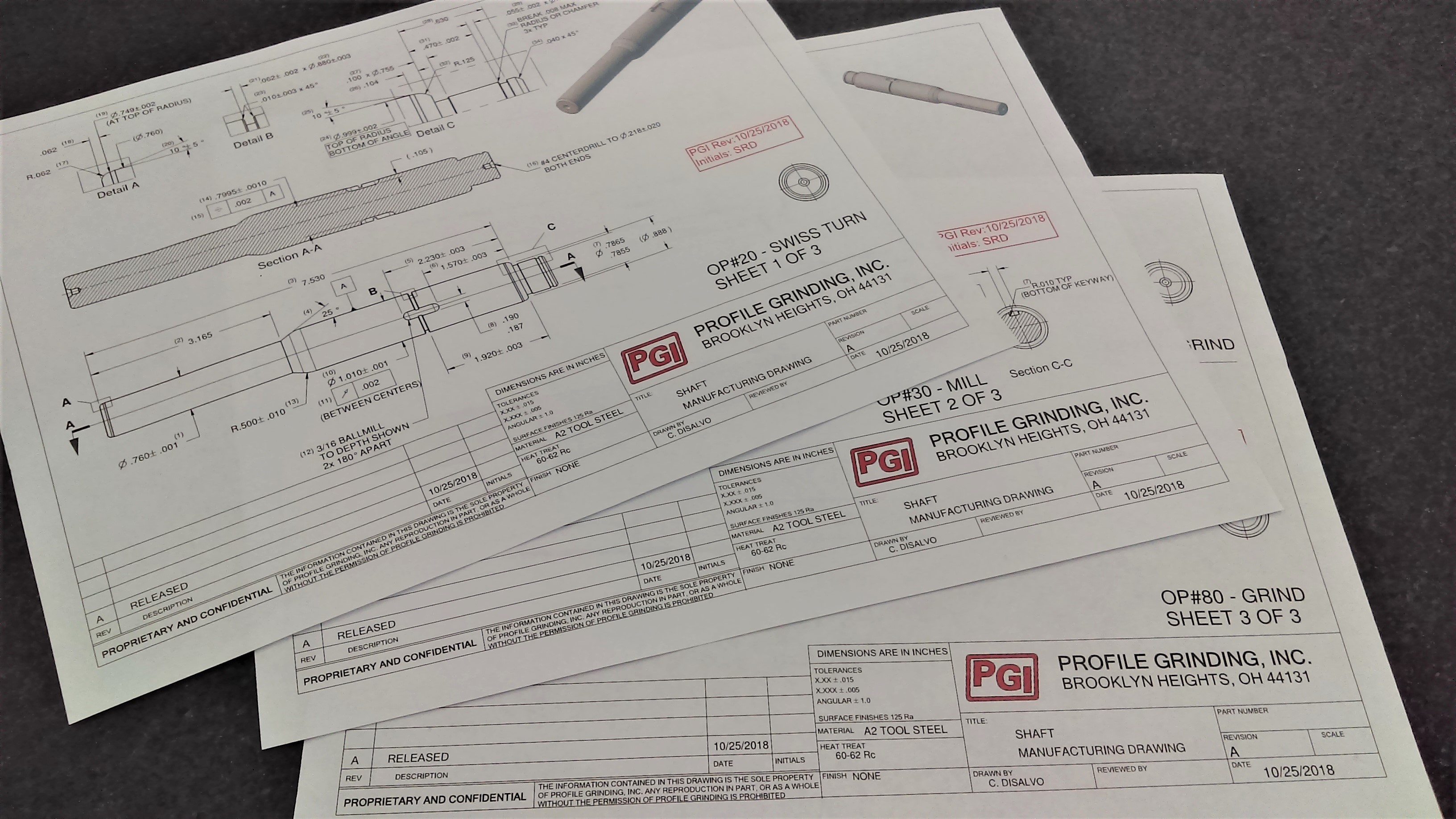

• Complex parts are supported by our in-process manufacturing drawings, developed to account for heat treat, pre-plate, and pre-grind dimensional allowances and other in-process operations, resulting in piece-after-piece precision.

• Lot Control is performed

• First Piece, In-Process, and Final Inspection data is recorded

• Pressure, Vacuum, and Leak Testing is performed, as appropriate

• Component Matching is employed to ensure an exacting fit, where necessary

We will provide quality data per your standard, as requested, and including:

• Material Traceability & Certification

• Material Treatment Certification

• PPAP (Production Parts Approval Process)

• SPC (Statistical Control Process)

• COC (Certificate of Conformance)

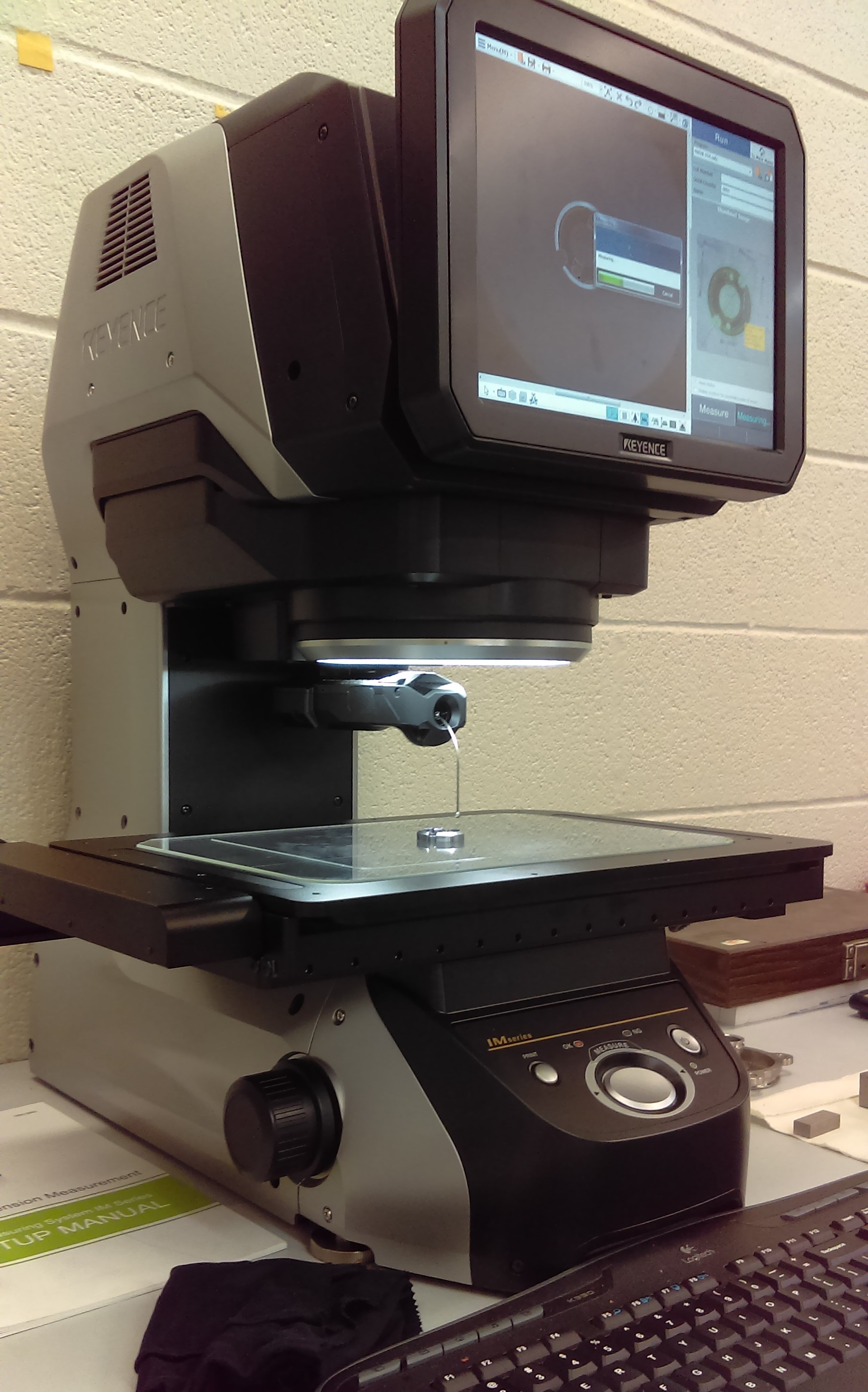

Our precision instrumentation includes, but not limited to:

• Vision Image Dimensional Measurement System

• Coordinate Measuring Machine (CMM)

• Roundness Tester

• Profilometer

• Digital Height Gage

• Vernier Calipers and Micrometers

• Gage blocks and pins

• Rockwell Hardness Tester

• Microscope

We appreciate your consideration. Contact us today!