Testing & Assembly Services

Prefer your critical components be design-tested before they reach your dock?

Profile offers functional testing services for manufactured complete components, and engineers and manufactures appropriate testing equipment to provide you confidence that every part performs as desired in the field.

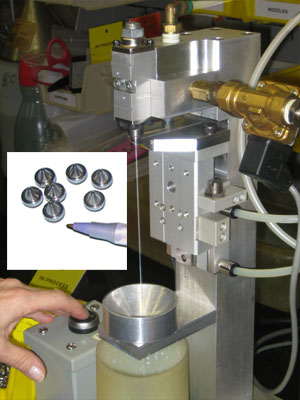

At bottom, industrial nozzles are tested for volume capacity, directional accuracy, and leak prevention while under pressure on equipment designed and manufactured by Profile.

Allow us to streamline your operations even further and provide assembly services- particularly for those assemblies which require component matching and/or post machining, as the poppet assemblies pictured at right.

Should your assembly require press, bolt, braze, or weld- we do that too. Pictured is a machined tube assembly with a brazed ferrule. After assembly, we pressure test it to 9600 psi.

Also pictured is an industrial needle kit, whereby we first manufacture a ball-brazed, precision-machined needle, engraved washer, and end cap. All components are pressed together to form the main assembly, which we then package in a clear, plastic container with protective padding and desiccant packet.

Other services include installation of thread inserts, SAE port plugs, expanding plugs, helicoils, and other functional design features.

Call Profile today to see how we can deliver more value!